Research focuses on applied materials chemistry, ranging from polymer chemistry and nanomaterials to basic synthetic-organic research. In recent years, both research into and the use of 3D printing technology using fused deposition modeling (FDM) has emerged as a successful core aspect of the research topics.

Chemistry in 3D-printed reaction vessels - 3D printing under inert gas conditions

3D printing technology can help chemists in many ways:

PROCESS 9/2018: Chemistry under pressure: What does the triumph of additive manufacturing mean?

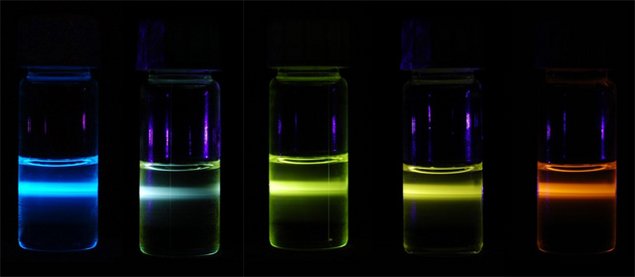

Printing true-to-scale models with precisely scaled bond lengths and angles is now a routine task. Over the last few years, the working group has developed 3D printing using FDM within an inert gas atmosphere for the production of closed and gas-tight reaction cuvettes . The vessels, which are pressure-stable up to 10 bar, allow the recording of IR, UV/Vis and NMR measurements without taking samples directly in the reaction vessel by 3D printing suitable geometries. No modifications to the spectrometers used are necessary in order to obtain complete reaction control or reaction mechanistic clarification. The complete NMR transparency of the non-deuterated matrix polymers used should be emphasized.

purmundus challenge 2018: 3D-printed reaction vessels - the path to the digital laboratory Handbook of Chemical Reactors, Springer Spektrum, 2018: Special laboratory reactors: 3D-printed reactors New J. Chem.2017, 41, 1925 - 1932: Sonogashira Coupling in 3D-Printed NMR Cuvettes: Synthesis and Properties of Arylnaphthylalkynes Helv. Chim. Acta 2016, 99, 255 - 266: 3D-Printing Inside the Glove-Box: A Versatile Tool for Inert-Gas Chemistry Combined with Spectroscopy Annual Report of Clausthal University of Technology Highlights 2015: FDM 3D printing under inert gas conditions

The inert gas environment provides a better layer adhesion of the FDM-printed objects. We were able to demonstrate a significant improvement of the mechanical properties by FDM printing under inert gas conditions, which should serve as a basis for the development of improved FDM 3D printers.

Prog. Addit. Manuf. 2016, 1, 3 - 7: Improved Mechanical Properties of 3D-Printed Parts by Fused Deposition Modeling Processed under the Exclusion of Oxygen

Modern materials

Functionalized monomers and polymers that carry N-donors as metal-binding ligands are being developed for 3D printing and other everyday applications. The development of reversible cross-linking induced by metal ions is of particular interest for the stabilization of biodegradable polylactides that are accessible from renewable resources.

Tetrahedron2017, 73, 4472 - 4480: Reaction of N-heterocyclic carbaldehydes with furanones - an investigation of reactivity and regioselectivity

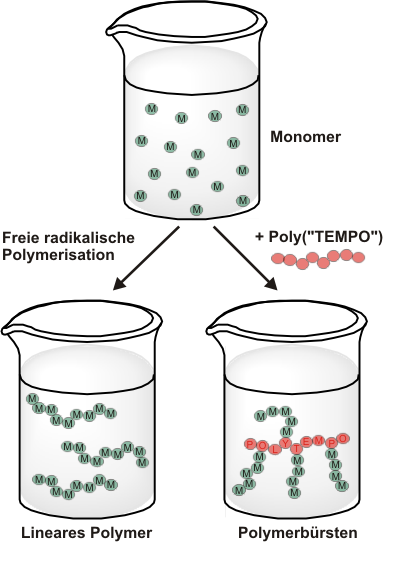

Other research projects focus on the construction of molecular architectures, one example being an impressively simple way to transform a free radical polymerization into a source of bottle-brush polymers.

Polymer2017, 111, 258 - 264: Radical polymerization of styrene in presence of poly(2,2,6,6-tetramethylpiperidine-N-oxyl-4-yl methacrylate) - formation of polymer brushes

Another example is the transfer of the concept of a "Velcro fastener" to the molecular level to create reversible compounds at the nanoscopic level.

Express Polym. Lett. 2018, 12, 556 - 568: Proof of concept for molecular velcro based on the attractive interaction between porphyrin and pyridine containing copolymers

Another area of research focuses on the production of well-defined and hybrid "single chain nanoparticles" (SCNP) by cross-linking N-donor-containing functionalized polymers using metal ions in highly diluted solution. The resulting particles have shown high catalytic activity in palladium-catalyzed cross-couplings.

Polym. Chem. 2017, 8, 7546 - 7558: Hybrid single-chain nanoparticles via the metal induced crosslinking of N-donor functionalized polymer chains

In addition to fundamental polymer-physical findings, this is seen as a starting point for the future production of catalytically active 3D printing materials. In the medium term, a complete set of reaction vessel geometries and catalytically active printing materials will be made available.

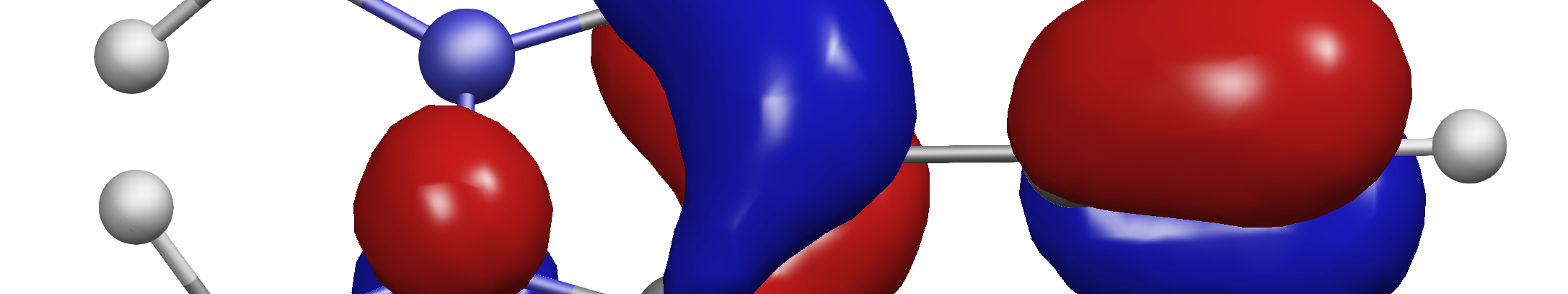

The practical work will be supported by accompanying theoretical investigations in the form of density functional theory calculations.

If you have any questions, please contact us directly by e-mail or telephone.